EQUIPMENT FOR TREATMENT

OF DISEASES OF VINES AND OTHER PLANTS

Efficiency and safe production

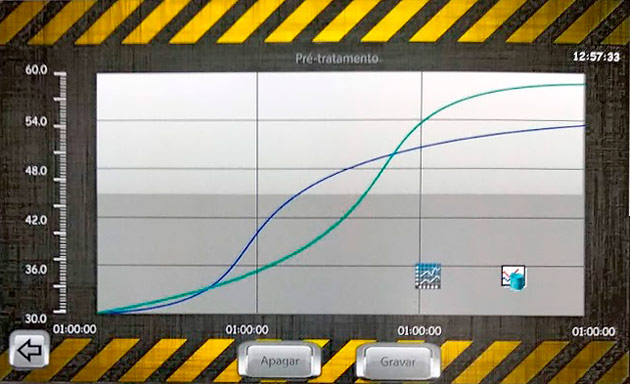

Control panel of the equipment

with a touch screen of 7 "ip 67 Panasonic brand.

The table allows:

- Check the heating temperature;

- Check the temperature of the tank in two different points (center of the basket and side of the tank);

- Registration of treatments performed;

- Export processing data for Excel sheet;

- Printing of treatment data;

- Control of water movement;

- Remote management of equipment (with a PC, tablet or smartphone);

- Control of the time of treatment with audible warning device;

- Management of the alarms of treatment;

- Check the saturation of the filter through the continuous control of the working pressure;

- Possibility of installation of a remote system to visualize the working parameters.

Basket treatment plants

Other features:

- Basket of treatment of strains with 2,000 liters of capacity.

- Cylindrical shape of the basket with 1270 mm of diameter of 1300 mm of height.

- Basket constructed with electro-welded steel rods.

- Reinforcement with aisi 304 stainless steel pipes.

- Production capacity of 5,000 vines / treatment.

- Basket with manual opening and removable side for easy filling of basket.

Thermal printer of the brand Zebra

- Thermal printer installed in the control panel.

- It prints at a resolution of 203 dpi at maximum speeds of 152 mm per second.

- Thermal transfer printing printer allowing direct printing of plastic labels for marking.

Dismountable hot water circulation inner tubes for easy cleaning.

Outras características:

- General construction in AISI 304 stainless steel with 2b finish.

- Equipment on the bench with 1200 mm wide by 2250 mm in length. It can not be carried full.

- Main treatment tank with a total capacity of 3,000 liters. Cylindrical shape of the tank with 1650 mm in diameter and 1700 mm in height. Manual opening covers.

- Insulation with polyurethane injected with 100 mm thickness.

- Saunier Duval water heating boiler with chimney output (the equipment is served with a meter of exhaust gas)

- Installation of the remaining chimney is the responsibility of the final customer. The exhaust pipe should be double wall with 26.7 kW with energy class “A”. Boiler should be fueled with gas.

- Boiler dimensions: 740 mm high, 418 mm long and 344 mm wide. Includes circulation pump in tank liner.

- Acoustic boiler level of 37.7 db. Forced boiler ventilation. Extraction of gases with double tube with exit of gases by internal tube.

- Pump, water circulation in the jacket, Ebara brand centrifuge with safety particle filter vessel accumulation. Maximum working pressure: 3 bar. Maximum circulating water temperature of 90˚C. Pump with ip55 protection. Three-phase 0.75 kW motor. Pump body, impeller and diffuser made of stainless steel. The entire interconnection shall be thermally insulated by special insulation of 19 mm thickness.

Use of Equipment.

This equipment is designed to perform treatments on the plants by immersion in hot water at a specified temperature for a specified time.

It is designed so that the temperature is homogeneous in all parts of the interior of the basket that contains the plants.

This is achieved with indoor diffusers and hot water recirculation.

This treatment is used for the vines of the vineyard before being grafted, in order to prevent the infection by golden flavescence and Xylella fastidiosa.

It can also be used to prevent some diseases in various types of plants, such as fruit trees.

The rods are introduced into the basket and submerged in hot water at a constant temperature of 50 ° C for 45 minutes.

It is equipped with a touch screen with a system of control and recording of the temperatures during the process, in order to be able to carry out the homologation and traceability of the process.

The heating of the water is done thanks to a propane condensing boiler.